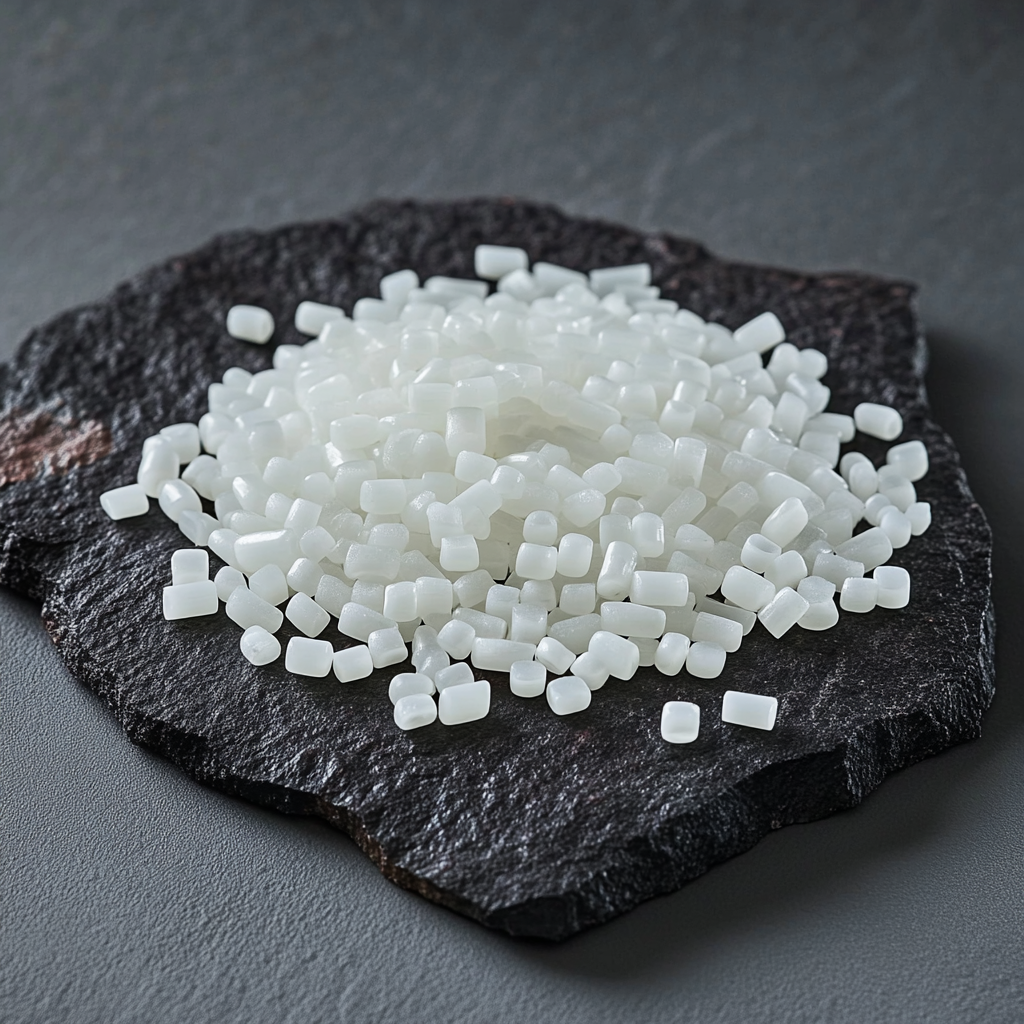

再生切片系列

R-CHIP SERIES

再生半消光切片 / 再生大有光切片 / 再生全消光切片

Recycled semi-dull chip / Recycled bright chip / Recycled full-dull chip

采用聚酯再生技术生产,可纺性能与原生切片完全一致。特别适用于超细旦高 F 涤纶长丝(如 FDY 15D/12F、FDY 20D/48F、DTY 20D/24F 等)的制造,其纺丝稳定性、纤维均匀度及后加工适应性均达到行业领先水平。

Manufactured via polyester recycling technology with spinnability equivalent to virgin chips. Specifically optimized for producing ultra-fine denier high-F polyester filaments (e.g., FDY 15D/12F, FDY 20D/48F, DTY 20D/24F), featuring industry-leading spinning stability, fiber uniformity, and post-processing compatibility.

再生无锑切片 / 再生阻燃切片

Recycled antimony-free chip / Recycled flame retardant chip

无锑半消光:

创新无锑催化体系确保产品无重金属残留,通过欧盟 EN71-3:2013 玩具安全标准检测,可广泛应用于婴幼儿服饰、贴身纺织品等高安全要求领域。

Antimony-free semi-dull:

Innovative antimony-free catalytic system guarantees no heavy metal residues, compliant with EU EN71-3:2013 toy safety standards. Ideal for high-safety applications such as infant clothing and intimate apparels.

阻燃:

含磷共聚阻燃聚酯切片,极限氧指数(LOI)≥32%,垂直燃烧测试达 UL94 V-0 级。可纺性优异,熔体稳定性 CV 值<3%,适用于消防服、装饰织物等阻燃纺织品生产。

Flame retardant:

Phosphorus-containing flame retardant copolyester chips with LOI ≥32% and UL94 V-0 rating. Excellent spinnability with melt stability CV<3%, suitable for fire-resistant textiles like fire suits and decorative fabrics.

再生常温常压阳离子切片

Recycled normal temperature/pressure cationic chip

基于阳离子改性技术,可在常温常压条件下实现纤维均匀染色。特别适用于生产色泽鲜艳的春亚纺、塔丝隆面料,与棉 / 毛等天然纤维混纺时可形成独特的麻灰效果,染色成本降低约 20%。

Cationic modification technology enables uniform fiber dyeing under normal temperature/pressure. Ideal for producing vibrant polyester fabrics like Chunya and Taslan. Blending with natural fibers (cotton/wool) creates unique mélange effects, reducing dyeing costs by ~20%.

再生高粘切片

Recycled high-viscosity chip

可定制特性粘度(IV)0.67~1.0dl/g 的再生 PET 切片,支持端羧基(≤25mol/t)、二甘醇(DEG≤1.2%)及粒径(2.5-4.0mm)的精准调控。主要用于轮胎帘子线(强度≥8.5cN/dtex)、汽车安全带、安全气囊等工业领域。

Customizable recycled PET chips with IV 0.67~1.0dl/g, offering precise control over carboxyl end group (≤25mol/t), DEG (≤1.2%), and particle size (2.5-4.0mm). Mainly used in industrial applications such as tire cord (tenacity ≥8.5cN/dtex), automotive seatbelts, and airbags.

再生低粘切片

Recycled low-viscosity chip

特性粘度(IV)0.45~0.60dl/g 的低粘切片,与常规切片共混后可纺制复合纤维。成品具有断裂伸长率≥400%、弹性回复率≥90% 的优异性能,广泛应用于运动服饰弹性面料、汽车内饰缓冲材料等领域。

Low-viscosity chips (IV 0.45~0.60dl/g) can be blended with conventional chips to produce composite fibers. The resulting yarns feature ≥400% elongation at break and ≥90% elastic recovery, suitable for sportswear elastic fabrics and automotive interior cushioning materials.

再生膜级切片(光学膜 / 离型膜)

Recycled film chip (Optical film / Release film)

光学膜:

采用多层共挤技术生产的光学级 PET 膜,雾度≤1.5%、透光率≥92%,表面粗糙度 Ra≤5nm。主要应用于 LCD/OLED 显示面板增亮膜、扩散膜,以及裸眼 3D 显示光学元件。

Optical film:

Optical-grade PET films produced via multi-layer co-extrusion, featuring haze ≤1.5%, transmittance ≥92%, and surface roughness Ra≤5nm. Used in LCD/OLED display brightness enhancement films, diffusion films, and 3D visualization components.

离型膜:

通过表面涂覆技术实现剥离力可控(1-50g/in),适用于 FPC 软板、偏光片、双面胶等精密电子元件制程。在 50℃高温高湿环境下剥离力保持率≥95%,符合 IPC-TM-650 可靠性测试标准。

Release film:

Controlled-release force (1-50g/in) achieved through surface coating technology, suitable for FPC flexible boards, polarizers, and adhesive tapes. Maintains ≥95% release force retention under 50℃/RH95% conditions, compliant with IPC-TM-650 reliability standards.

再生瓶级切片

Recycled bottle grade chip

采用固相缩聚工艺生产,特性粘度(IV)0.70~0.85dl/g,乙醛含量≤1.0ppm。晶体结构均匀度 CV 值<2%,可用于制造 500ml-20L 食品饮料包装瓶,满足 FDA、EU 10/2011 等食品接触材料安全标准。

Produced via solid-state polycondensation with IV 0.70~0.85dl/g and acetaldehyde content ≤1.0ppm. Uniform crystalline structure (CV<2%) ensures suitability for 500ml-20L food/beverage packaging bottles, compliant with FDA and EU 10/2011 food contact safety standards.

电话:0558-4148866

电话:0558-4148866

邮箱:ir@yyfiber.com.cn

邮箱:ir@yyfiber.com.cn

地址:安徽省阜阳市颍上县慎城镇经济开发区管鲍路北侧分金路东侧

地址:安徽省阜阳市颍上县慎城镇经济开发区管鲍路北侧分金路东侧